COTS Competition Rocket

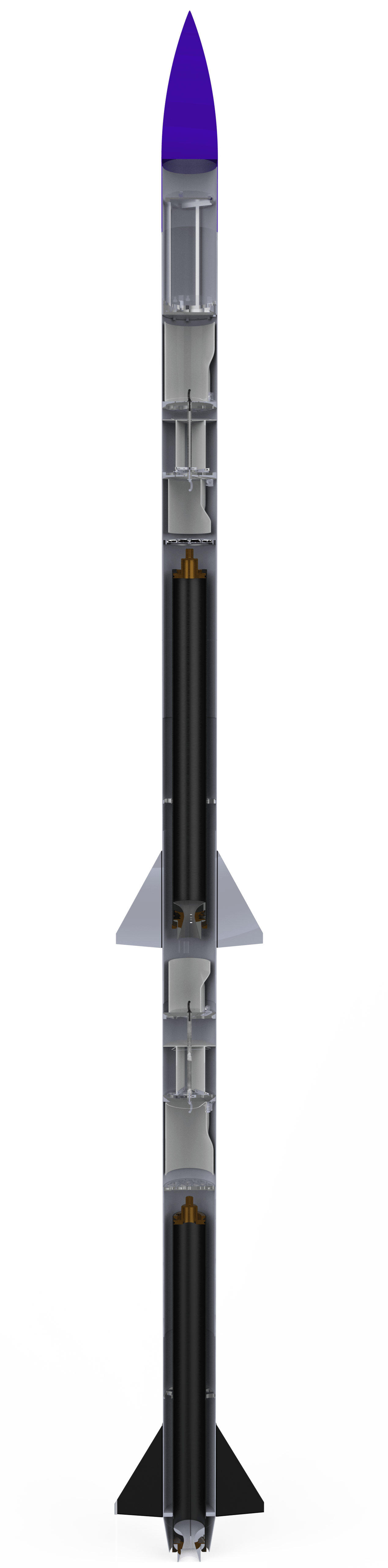

COTS, or “Commercial-off-the-shelf” rockets, is a category within rocketry competitions that allows a team to purchase up to 100% of the rocket's components and remain eligible for a podium placement. Our COTS team manufactures an impressive 85% of the rocket in-house, allowing for extensive teaching on rocket design and manufacturing for interested students. Our COTS competition rocket is an excellent opportunity for both experienced and non-experienced students to build a rocket from the ground up.

2025-26 COTS Rocket in production: CLOUDBURST

Payloads Subteam

The payloads subteam often designs either an engineering demonstration or a scientific experiment for the rocket to carry. The payload is what you make of it, so members have the chance to provide ideas on what to build next and can often choose what type of work they want to do. The entire project often requires simulations, prototyping, testing, and manufacturing. Depending on the chosen project, work could include electrical prototyping, PCB design, microcontroller programming, machining, 3D printing, mechanical design, and even biological or chemical lab work!

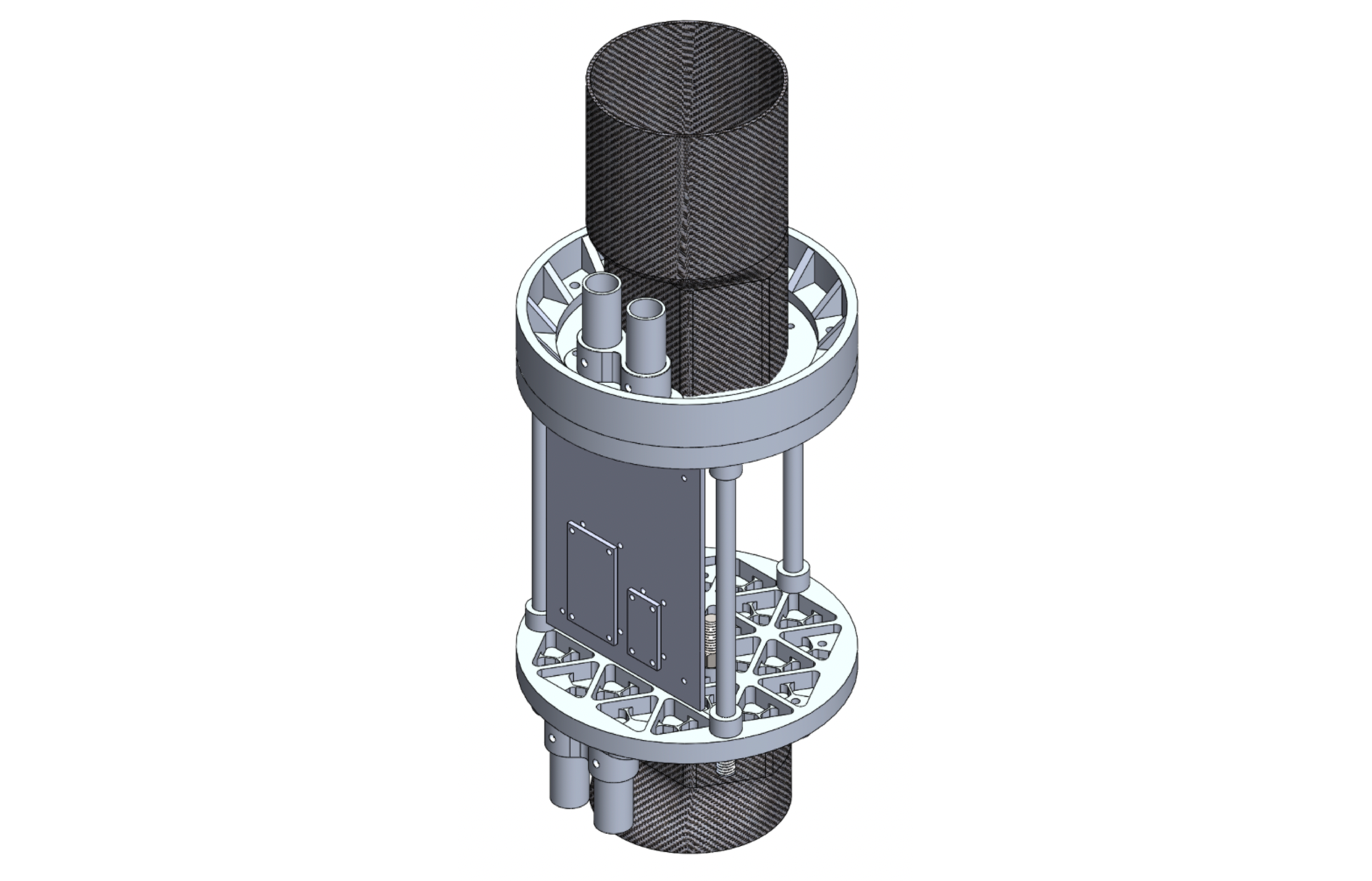

Internals Subteam

The internals subteam is responsible for designing and manufacturing structures that secure our avionics, payload, propulsion, and recovery systems. In the first half of the year, members focus on designing their models and assemblies using SolidWorks, emphasizing weight reduction and Design for Manufacturing and Assembly (DFMA) principles. In the second half of the year, students learn various manufacturing methods, including manual machining, CNC machining, water jet cutting, and composite layups.

Aerostructures Subteam

Aerostructures is a manufacturing-heavy subteam. Members will learn how to safely prepare and infuse numerous fiberglass and carbon fiber composite components, such as bodytubes, fins, and a nosecone. The processes we employ require high levels of detail and individuals committed to ensuring the process is right every single time. This is an excellent opportunity for students to be hands-on with rocket fabrication, learn the complexities of aerospace composite materials and become familiar with a plethora of workshop tools.

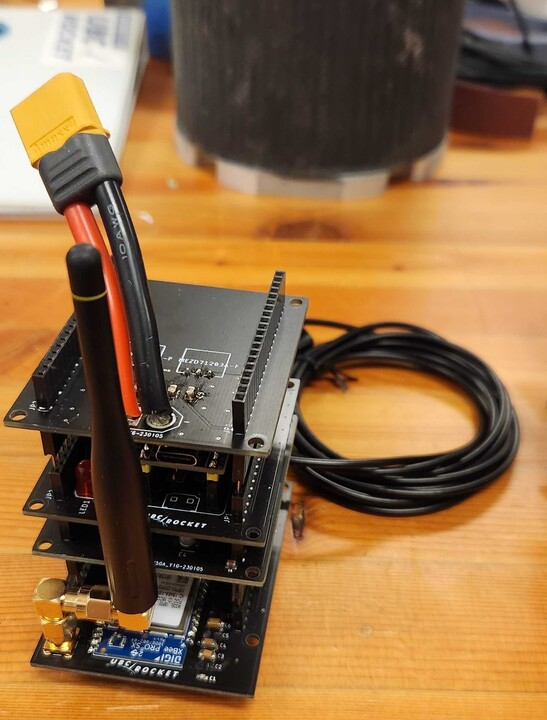

Avionics Hardware Subteam

The avionics hardware subteam focuses on the full scope of avionics system development for the rocket. We design, build, test, and debug the avionics electronic hardware for the COTS rocket projects. Team members can expect to learn a lot about PCB design, PCB assembly, and electronics testing.

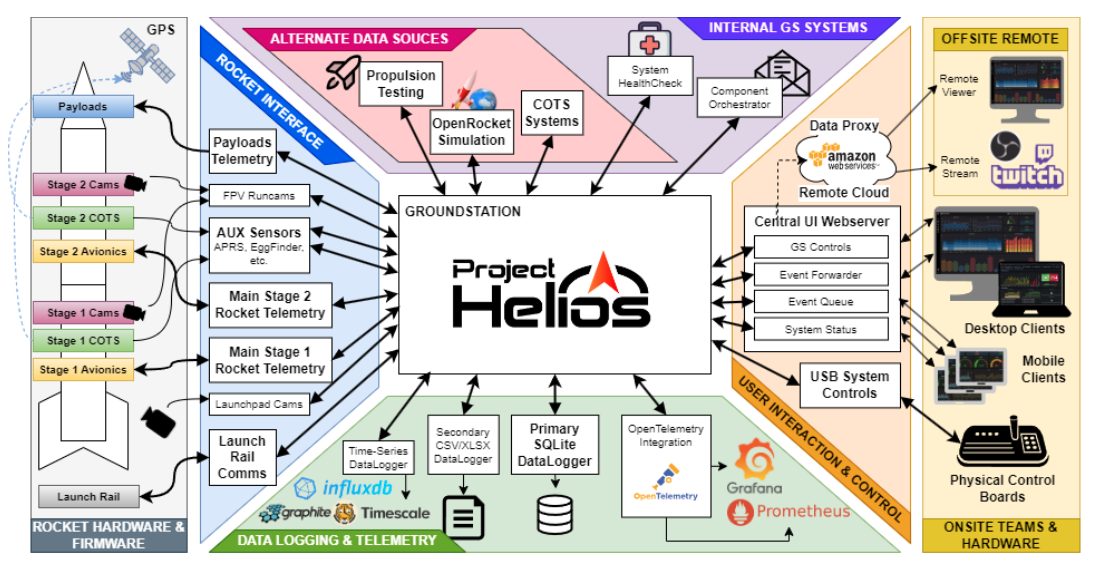

Avionics Software Subteam

Members of the avionics software & firmware subteam are responsible for the digital systems of our 30,000 ft competition rocket. All members will help construct FLARE, the code that powers real-time telemetry collection on the physical rocket in addition to developing Helios, our cutting-edge experimental ground station software. On the firmware side, students will learn learn embedded systems programming, sensor integration, and wireless communication protocols. On the software side, students will master handling high-speed data streams, creating intuitive interfaces, and applying agile methodologies in a fast-paced engineering environment.

Recovery Subteam

The recovery subteam is focused on the production and testing of toroidal and hemispherical parachutes, carbon fiber parachute bays, and black powder charges. Members learn how to design complex parachutes, fabricate internal recovery bays to house said parachutes, and configure critical deployment sequencing to bring the rocket down gracefully and colorfully. Key skills taught on recovery include detailed sewing techniques, extensive 3D printing, and composite materials manufacturing.